DX-27 high-efficiency micro-cracked hard chrome intermediate is one kind of solid powder intermediate, which can significantly improve the current efficiency, reduce the corrosion of anode plate caused by the plating solution. It makes the surface of finished product is more smooth and brighter, increase the hardness of the coating layer, and produce more micro cracks, with higher corrosion resistance. When it’s used in decorative chromium plating, it can accelerate the deposition and dispersion ability of plating solution, and is often used as the main component of the solid chromium plating additive. It can be directly used in solid form.

DX-27 high efficiency hard chrome plating intermediate

DX-27 high-efficiency micro-cracked hard chrome intermediate is one kind of solid powder intermediate, which can significantly improve the current efficiency, reduce the corrosion of anode plate caused by the plating solution. It makes the surface of finished product is more smooth and brighter, increase the hardness of the coating layer, and produce more micro cracks, with higher corrosion resistance. When it’s used in decorative chromium plating, it can accelerate the deposition and dispersion ability of plating solution, and is often used as the main component of the solid chromium plating additive. It can be directly used in solid form.

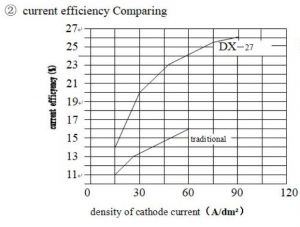

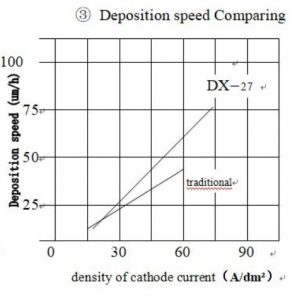

Features of DX-27 super high speed technology

Due to its simple process operation and high impurity tolerance of the solution, it is especially suitable for electroplating general mechanical parts as well as ordinary molds.

New solution is formulated as following: CrO3 250g/L, DX-27 5g/L,

Then add some H2SO4 to make CrO3:H2SO4 rate is between 1-1.1:100.

STEPS:

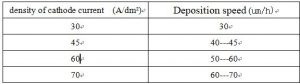

Reference value

| Parameter name | Parameter values |

| Status: | White powder |

| Molecular formula: | NaSO3CH2SO3Na |

| Molecular weight | 220.12 |

| Content: more than | 99% |

| File name | Download |

| DX-27 Intermediates |

DONGGUAN JINGJINGSURFACE TECHNOLOGY INC address:Changsheng industrial park NO.64 keji midway Shijie Town, Dongguan City, Guangdong

Phone number:+8613790181730

North America address: 3054 knollwood ave la verne ca 91750

Phone number: +16268636126

Email: jingjinggddg@gmail.com

Error: Contact form not found.