DX-30 Ultrahigh speed Technology is one of the Ultra-high-speed additives in hard chrome plating industry around the world, It is high efficiency, steady performance, reduces energy consumption., largely utilized in aeronautical, weapon, auto, motor and machinery industry. It evidently lowers product cost, improve final products quality and performance. All those make DX-30 the perfect combination of value and price.

Due to its high speed and high hardness, it is suitable for automotive, motorcycle parts and printing cylinder plating.

Its ultra-high deposition speed, so especially suitable for for roller, shaft and large-area plate plating

Elements and Operation Standards of Chrome Plating DX-930 Technology

Plating Bath Solution Formula of DX-30 Ultrahigh speed Technology

New solution is formulated as following: CrO3 240g/L, DX-30 25g/L),

Then add some H2SO4 to make CrO3:H2SO4 rate is between 1-1.1:100.

STEPS:

Plating Bath Solution Transfer

It has to be tested and studied by our company before transferring the plating bath solution.

For the traditional tech, we can adjust the contents of CrO3 and H2SO4 to the proper rate against the DX-30 standard, and then add DX-30.

For other technology, generally speaking, directly add DX-30 and adjust the amount of elements against actual conditons.

Note: The performance of plating solution after transfer is somehow influenced by original one, clients should keep us informed with any possible sitiations.

Supplements and Maintain of Plating Bath Solution

The consumption of CrO3 and catalyst has to be calculate by 1000Ah unit. Add DX-30 0.7g and CrO3 115g per 1000Amh during plating, or every time add 100kgs of CrO3, simultaneously add 5kgs DX-30, to keep the rate steady between CrO3 and catalyst. Reduce the consumption caused by convulsion as less as possible, recycle the solution with clean water, lower the waste and prevent the solution from disproportionation. Supplement is conducted against the above standard, during production, adjustment is made according to actual conditons.

Other Concerns and Notices

Voltage 12-15V, derect-current output, ripple factor≤3%.

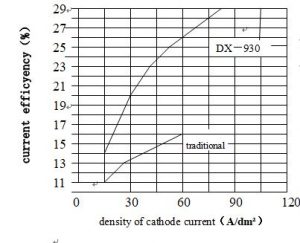

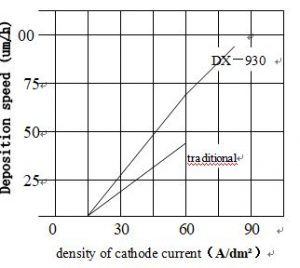

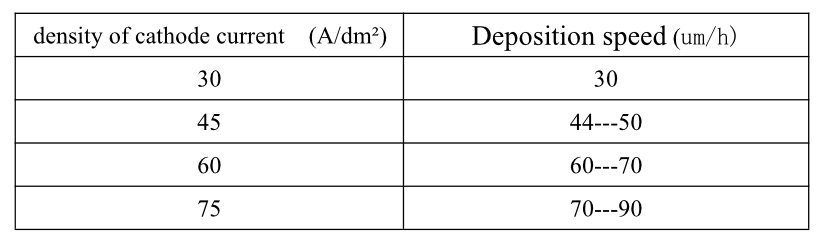

Reference value

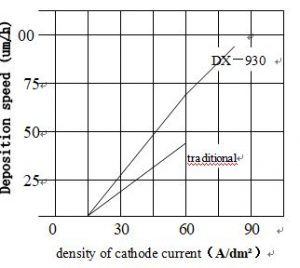

① Deposition speed

Reference value

① Deposition speed

| File name | Download |

| ST—930超高速镀硬铬工艺 |

DONGGUAN JINGJINGSURFACE TECHNOLOGY INC address:Changsheng industrial park NO.64 keji midway Shijie Town, Dongguan City, Guangdong

Phone number:+8613790181730

North America address: 3054 knollwood ave la verne ca 91750

Phone number: +16268636126

Email: jingjinggddg@gmail.com

Error: Contact form not found.